Reliable Solution | ETA Approved | High Load Capacity | Precision Installation

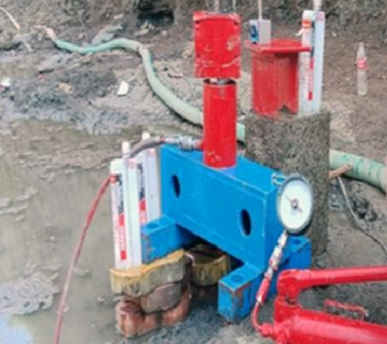

Rock Anchoring by using ICFS CM585PE-PRO Pure Epoxy Injection Mortar

Rock Anchoring in Indian Conditions Using ICFS CM585 Pure Epoxy Mortar :A Field Study in Collaboration with COEP and Viraj Engineers

Objective

To determine the safe pull-out capacities and bonding performance of steel rebars anchored in rock strata using ICFS CM585 Pure Epoxy, under realistic site conditions in India.

Background & Challenge

With growing demand for high-rise construction, deeper foundations often reach rock strata where hydrostatic uplift pressures become significant. Traditional anchoring methods are slow, costly, and poorly suited for wet, uneven surfaces. There's been a lack of documented performance data under Indian conditions.

Methodology

Sites: Two live construction sites in Pune with different rock types intact bold and bold rock.

Testing Oversight: Dr. Inshwar Sonar (Assistant Professor, COEP), with certified calibrated equipment.

Data Captured: Pull-out strength, elongation, failure modes.

Key Findings

Bond Stress: Decreased with bar diameter (e.g., 16mm: 7.2 T/mm, 32mm: 5.71 T/mm)

Max Stress: 32mm bars showed highest bond strength (3.38 MPa) due to greater surface area

Rock Influence: Intact basalt out performed fragmented rock by 15-20%

Failure Modes: Predominantly failures found of rock breakage and no bar fractures

Anchor Orientation: Vertical and horizontal anchors showed comparable performance with proper installation technique

Design Recommendations

Account for rock type, bar diameter, moisture levels and orientation

Use site-specific pull-out values to design anchor embedment depths

ICFS CM585PE is suitable for demanding conditions like uneven, water-exposed rock surfaces

Conclusion

For structural rock anchoring using pure epoxy injectable mortars, this first of its kind field study validates the application in Indian geology. ICFS CM585PE provides a reliable, tested alternative to conventional systems, ensuring both speed and safety in modern foundation engineering.

Description

CM585 is a 2 component high strength pure epoxy chemical anchoring resin system. It is designed for deep embedment and large diameter holes due to its zero shrinkage and longer working times. For diamond drilled holes, with rebar, and in areas of high chemical exposure eg. Seasalt and swimming pools.

Specific Benefits

Rock Anchoring Jobwork / Services

View

Rock Anchoring Jobwork / Services

View

Rock Anchoring Jobwork / Services

View

Rock Anchoring Jobwork / Services

View